Temporary Immersion Micropropagation

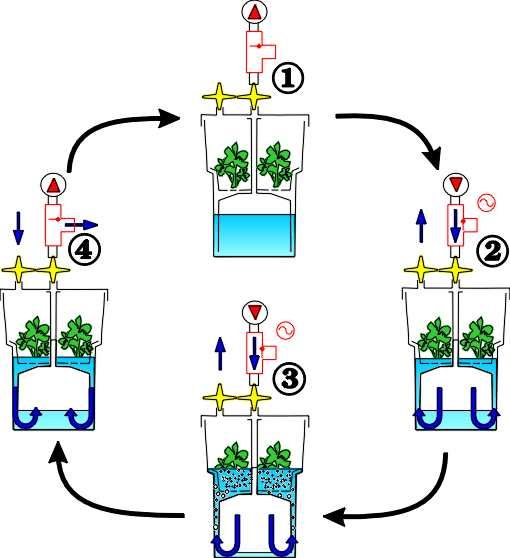

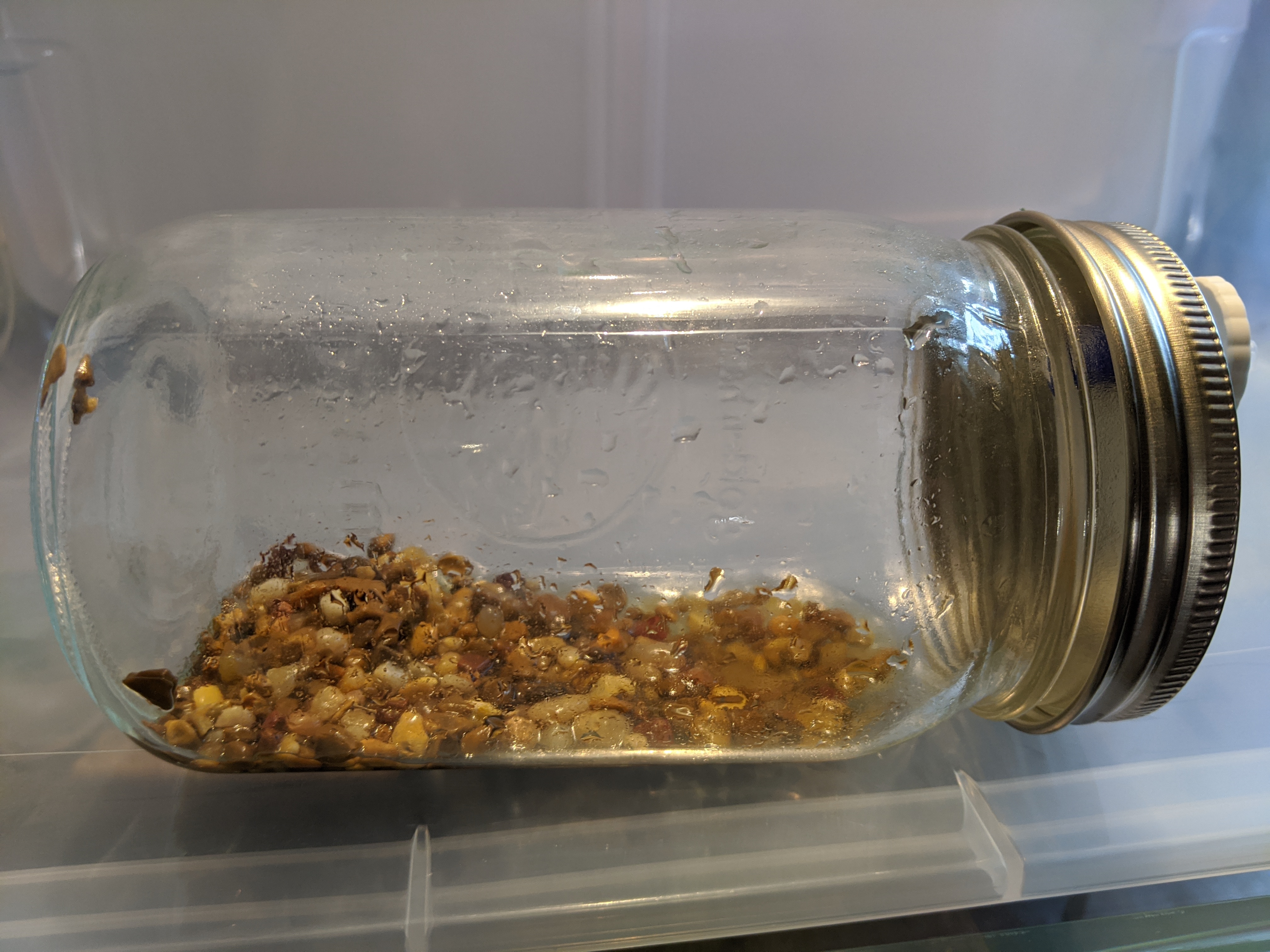

The newly devised temporary

immersion system relies on a large mouth mason jar

with a thin layer of pebbles to hold the explants in

place. A small amount of nutrient fluid bathes the

explants when the jar is on its side, and the jar is

tipped automatically to drain the nutrient solution

away from the explants. A 0.22 micron filter allows

gas exchange while maintaining sterility.

Jar on Side Floods Explants with Nutrient

Tipped Jar

Causes Nutrient to Recede

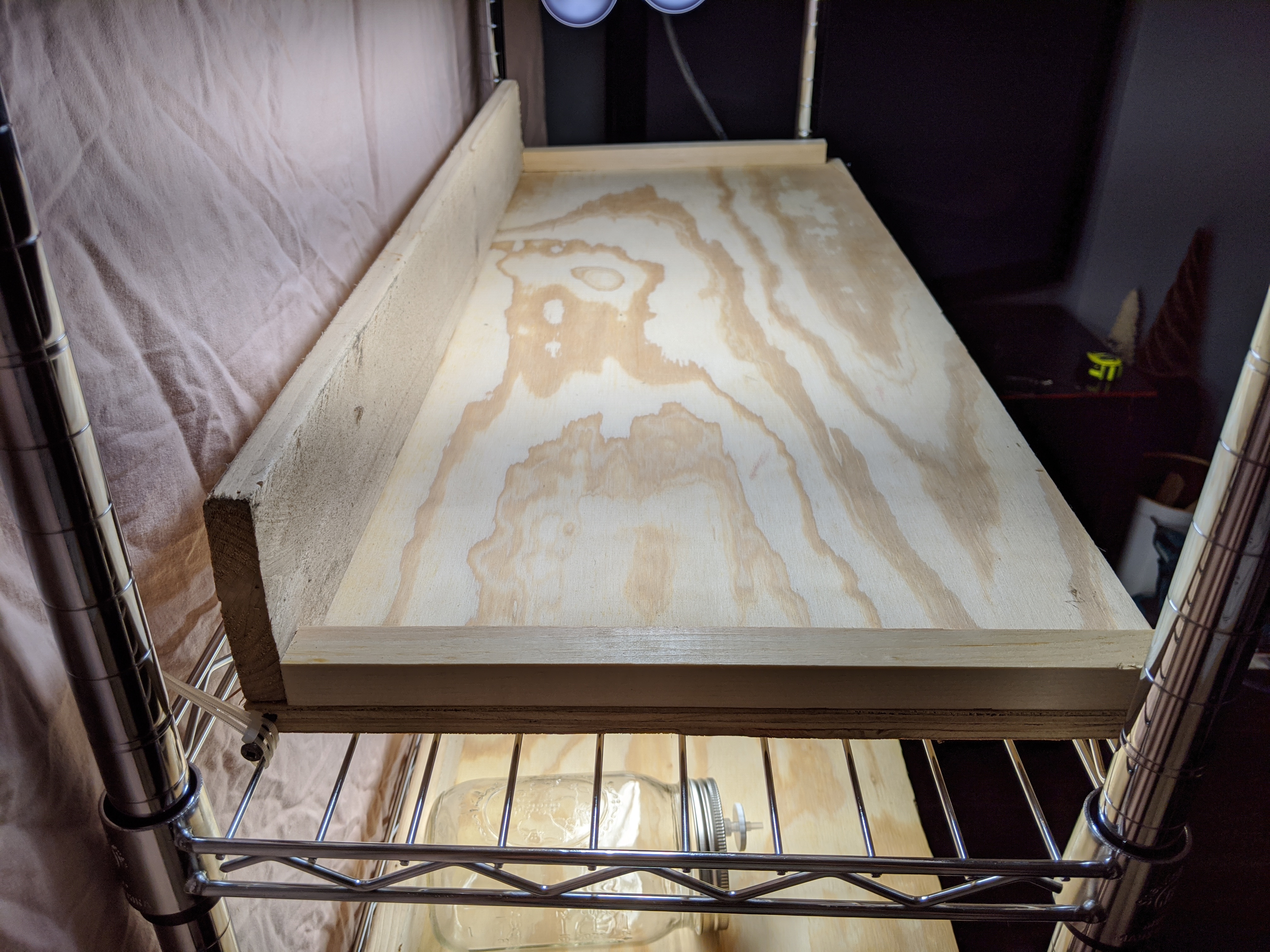

A tipping rack is made of wood and mounted

on a heavy duty wire shelf with a fulcrum anchored at one

side and a the other side raised by a motor. The motor is

controlled by an Arduino microprocessor that can be

programmed to specify customized tilt time and immersion

time. Multiple tipping tables will be linked to one motor

drive unit within a single 3 to 5 level shelf. This will

accomodate 8 jars per shelf, and up to 15 jars per shelf if

jars are stacked.

The

tipping rack automatically reclines and inclines on a

preset timing interval

Materials and

Equipment:

Pebbles - for holding explants in place

Stainless

Steel Lids - normal lids will rust

1/8"

Luer bulkhead adapter - filter attachment

1/4"

O-ring for sealing bulkhead adapter

32" x 14" x 1/2" plywood - for tipping shelf

1" x 4" x 8' pine board - for tipping shelf

3" screws

Stepper Motor Mounting Bracket

2" x 1/8" aluminum bar - for mounting motor

Traxxas ball joints - lift arm joint

M4 x 20mm set screws - lift arm

4" to 5" hole saw - cutting lift/drive wheel (a

jigsaw would also work here)

We Vitro Bioreactor -

this bioreactor would also work and may be preferable to mason jars because you can more easily manipulate plantlets from above.

Cost:

The cost of the

shelving, lighting, and tipping mechanisms for three

levels of tipping shelves is about $270.00, with almost

$190.00 in the wire shelf and LED lighting, which you

would need for static gel culture anyway. Cost for each

bioreactor is just over $7.00 ea. With a maximum of 45

bioreactors per shelving unit ($315.00 in bioreactors).

Assembly

Instructions:

Begin by

assembling the wire shelf, placing the bottom shelf 16

inches from the ground. Place the subsequent shelves 12

inches apart. The last shelf should be nearly at the top.

This will allow you to store supplies or static cultures

below the bottom shelf and have 3 tipping shelves.

LED lights require

being wired to a chord and plug and then can be zip-tied

in a central position under each of the top 3 shelves.

Chords can be made different lengths to accommodate

varying heights of shelves so you don't have to deal with

extra chord.

Assemble the

wooden tipping shelves by cutting 1/2" plywood into 32" by

14" rectangles. Also cut the 4" x 1" board into 32"

lengths. Align the long edges of the 4" by 1" board with

the plywood and affix with a screw or nail.

Scrap pieces of

wood can be nailed to either end of the shelf to prevent

jars from rolling off. A screw is inserted near the vertex

at either end of the boards to act as an anchor point for

the shelf to pivot. Zip ties anchor the tipping shelf to

the wire shelf.

Anchor the wooden

shelf to one side of the wire shelf using several zip ties

at each pivot point.

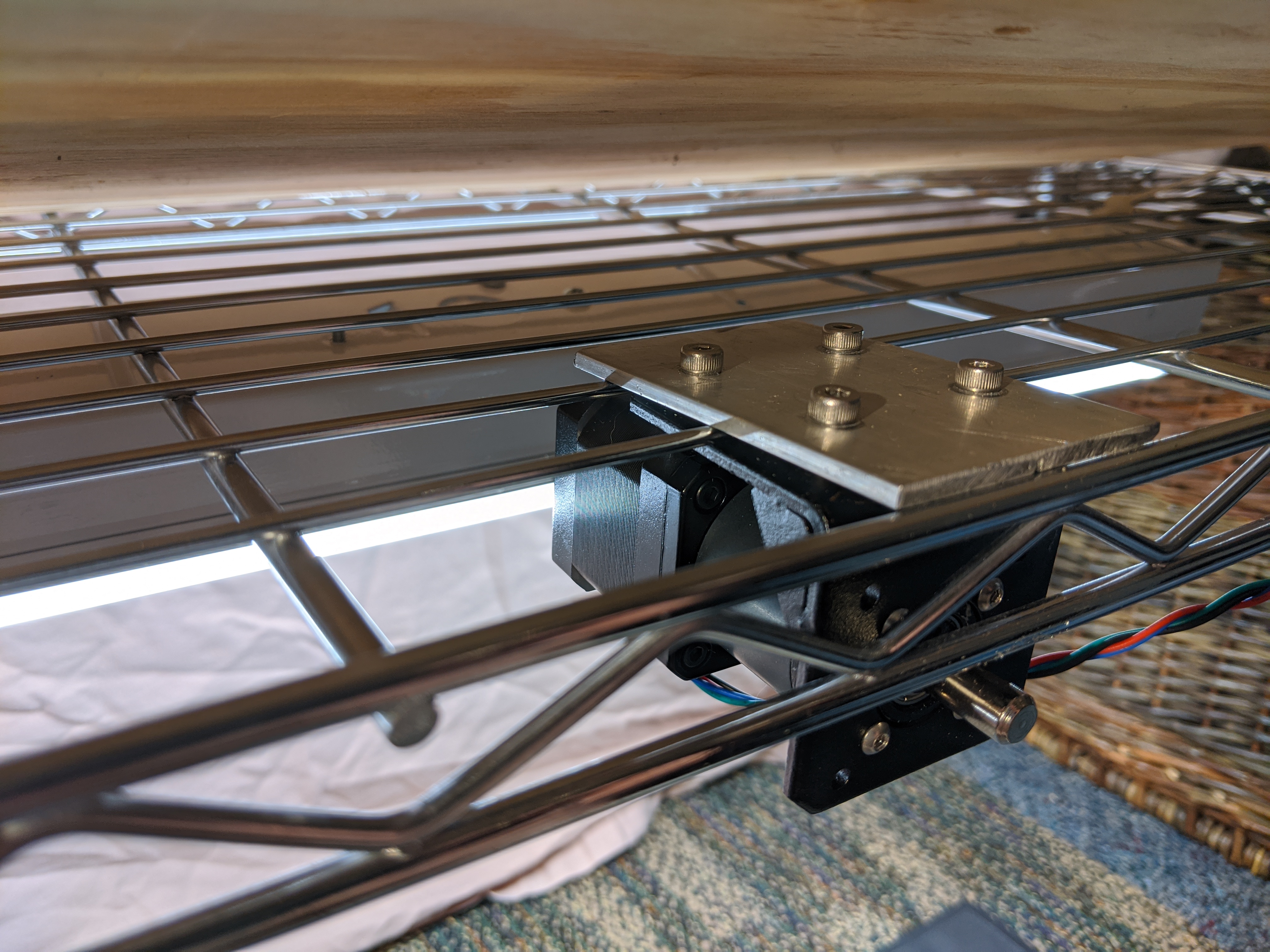

Cut a 4" section

off of the 2" by 1/8" aluminum bar and mark the center, at

2 inches. Place the stepper motor mounting bracket over

the aluminum bar and mark the position of 4 holes centered

on the 4" aluminum bar. Drill the 4 holes through the

aluminum bar large enough to accommodate an M8 bolt.

Sandwich the wire

shelf between the stepper motor mount bracket and the

aluminum bar at the middle and side of the wire shelf.

Place the M8 bolts through the holes in the aluminum bar

and the stepper motor mount bracket to affix the assembly

to the wire shelf.

Use the 4 M3 bolts

to mount the stepper motor to the mounting bracket.

Cut a 5" circle

out of the 1/2" plywood and thoroughly sand the edge to

smooth the wood. Use 4 short wood screws to mount the

flange coupling connector to one side of the wood circle

so it will be turned eccentrically. This is the lifting

mechanism for the shelf. Mount this on the shaft of the

stepper motor ensuring that one set screw seats on the

flat side of the shaft.

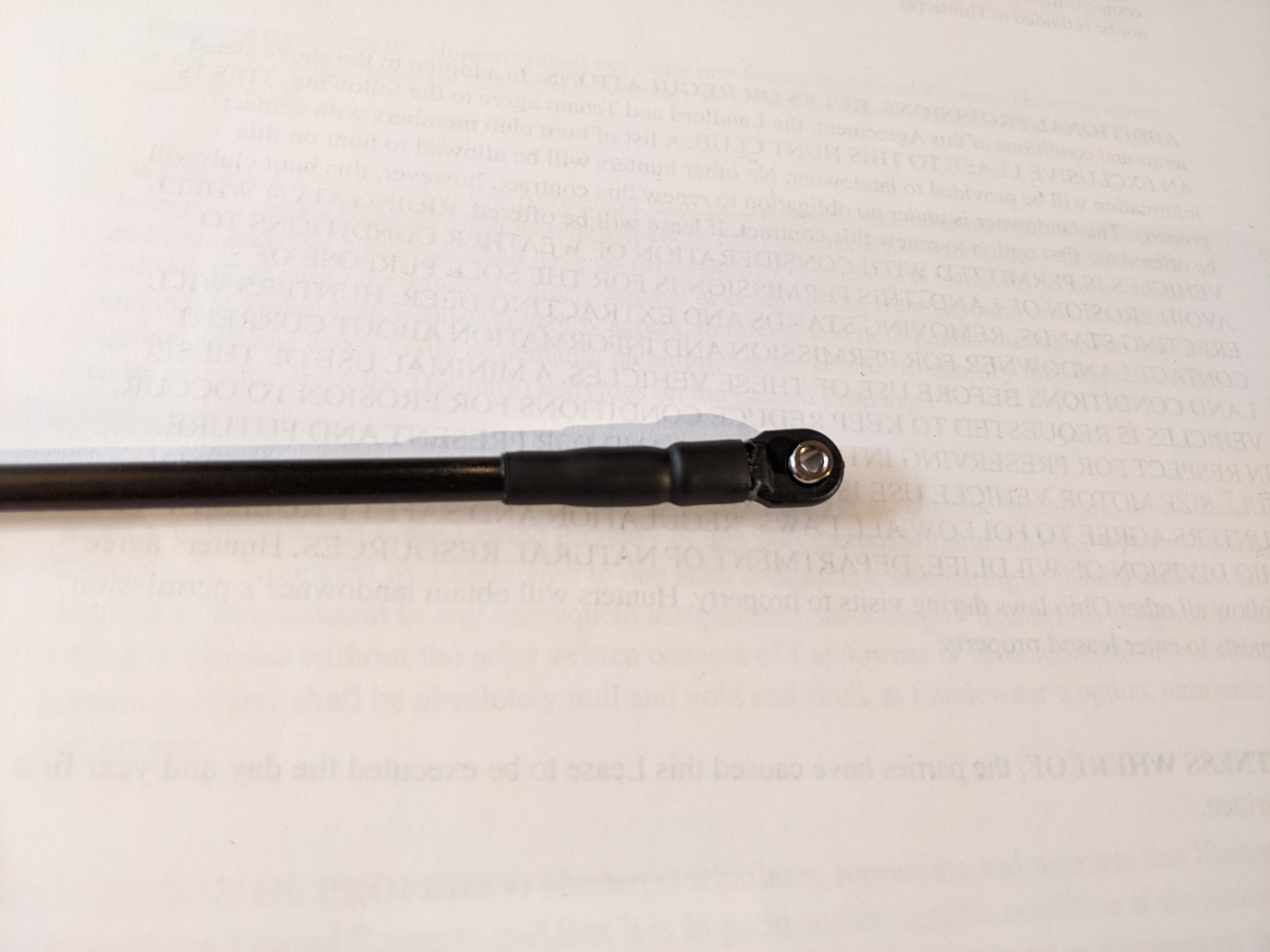

Measure the

distance between two adjacent shelves, subtracting the

length of two of the Traxxas joints (2 x 5/8"). This

should be about 10-3/4". Cut two carbon tubes to this

length.

Wrap 1.5 cm of

each end of the carbon tube with thread to reinforce the

end. Soak the tread with cyanoacrylate (super glue). Use a

M4 tap to cut threads into the ends of the carbon tubes to

accept the M4 set screws.

Screw the set

screw into the Traxxas ball joint. Slip two 1" long pieces

of heat-shrink tubing over the carbon tube and then screw

the Traxxas ball joints into each end to the carbon tube.

Use a hair dryer, heat gun, or flame to shrink the

heat-shrink tubing over both the Traxxas ball joint and

carbon tubing. This finished rod is called the "lift rod".

Screw two lift

rods into the far ends of two adjacent shelves. Repeat

this process with each pair of shelves. Your lift shelves

will finally all be linked to raise and lower in unison,

driven by the single drive wheel.

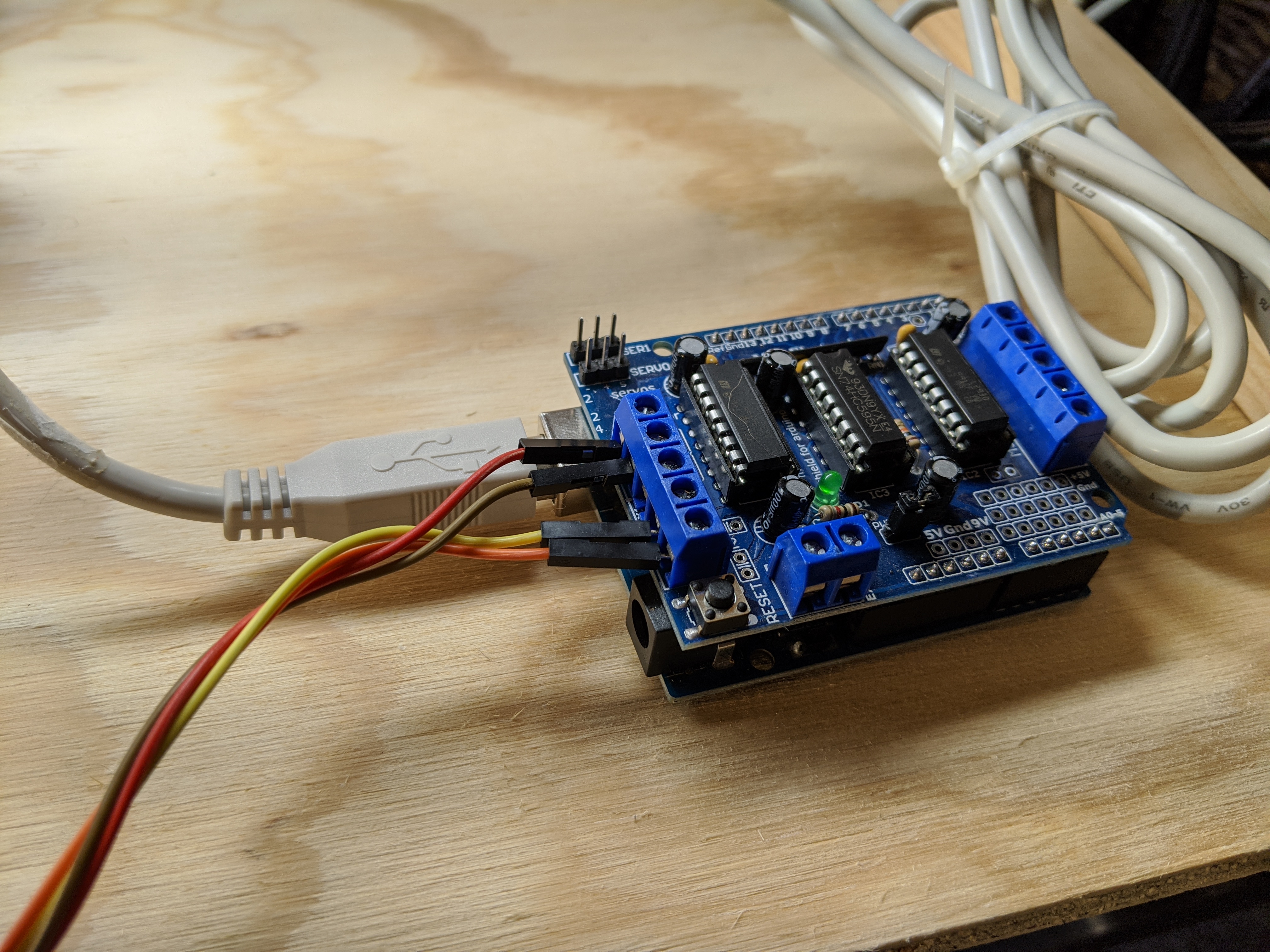

Mount the stepper

shield onto the Arduino and mount the wires in the 5

contact strip on the side of the stepper shield next to

the USB port. The black and green wire go in adjacent

connectors and blue and red wires go in adjacent

connectors, leaving the middle connector open.

Download Arduino

IDE to a computer and open a new sketch. Under the heading

"Tools" select "Manage Libraries" and install Adafruit

Motor Shield Library. Paste the following code into the

sketch.

//139:1 Stepper Motor Drive Sketch for Temporary Immersion Tilt Table

#include <AFMotor.h>

// to motor port #1 (M1 and M1)

AF_Stepper motor(100, 1);

void setup() {

motor.setSpeed(50); // 50 rpm

}

void loop() {

motor.step(3500, BACKWARD, MICROSTEP); //Amount of rotation backwards. 3500 steps for 51:1 motor

motor.step(3500, BACKWARD, MICROSTEP); //10500 total steps for 139:1 motor

motor.step(3500, BACKWARD, MICROSTEP); //Steps must be broken into increments for large step numbers

delay (60000); //Soak time

motor.step(3500, FORWARD, MICROSTEP); //Amount of rotation forwards

motor.step(3500, FORWARD, MICROSTEP);

motor.step(3500, FORWARD, MICROSTEP);

motor.release(); //shuts off power to motor

delay (3500000); // 30min ~ 1500000 //Tilt time

//This code down below is is for other step modes if you wish to experiment

//Serial.println("Double coil steps");

//motor.step(100, FORWARD, DOUBLE);

//motor.step(100, BACKWARD, DOUBLE);

//Serial.println("Interleave coil steps");

//motor.step(100, FORWARD, INTERLEAVE);

//motor.step(100, BACKWARD, INTERLEAVE);

//Serial.println("Micrsostep steps");

//motor.step(100, FORWARD, MICROSTEP);

//motor.step(100, BACKWARD, MICROSTEP);

}Connect your computer to the Arduino board with a USB cable, select the proper COM port and Board under the "Tools" tab. Select "Verify" and then select "Upload" to upload the sketch to your Arduino board. The motor should now begin to turn. Unplugging the USB chord will reset the sketch, so you can allow the wheel to rotate and unplug when the wheel and shelf are at their highest position. Adjust the "Soak time" and "Tilt time" to achieve your desired results and then re-upload the sketch.

Jar lids must be drilled with a 1/4" drill bit to allow the bulkhead adapter and 0.22 micron filter to be attached. Use a silicon o-ring to seal the bulkead fitting.

Dump a small

amount of pebbles into the mason jar so they are two

pebbles deep on the bottom of the jar. Mix up nutrient

medium and pour between 25 and 30 ml of medium into the

mason jar. Loosely attach the lid and autoclave it in a

pressure cooker for 15 minutes at 15 psi.

In a laminar flow

hood or other protected place, shake pebbles and medium

onto the side of the jar. Cut explant into nodal cuttings

and poke the nodal cuttings into the pebbles in the half

of the mason jar next to the jar opening. Close the lid

firmly and place the jar on the tipping shelf and be sure

that the tipping cycle is operating appropriately.

Happy Growing!

Relevant Literature:

An efficient temporary immersion system for micropropagation of hybrid hazelnut