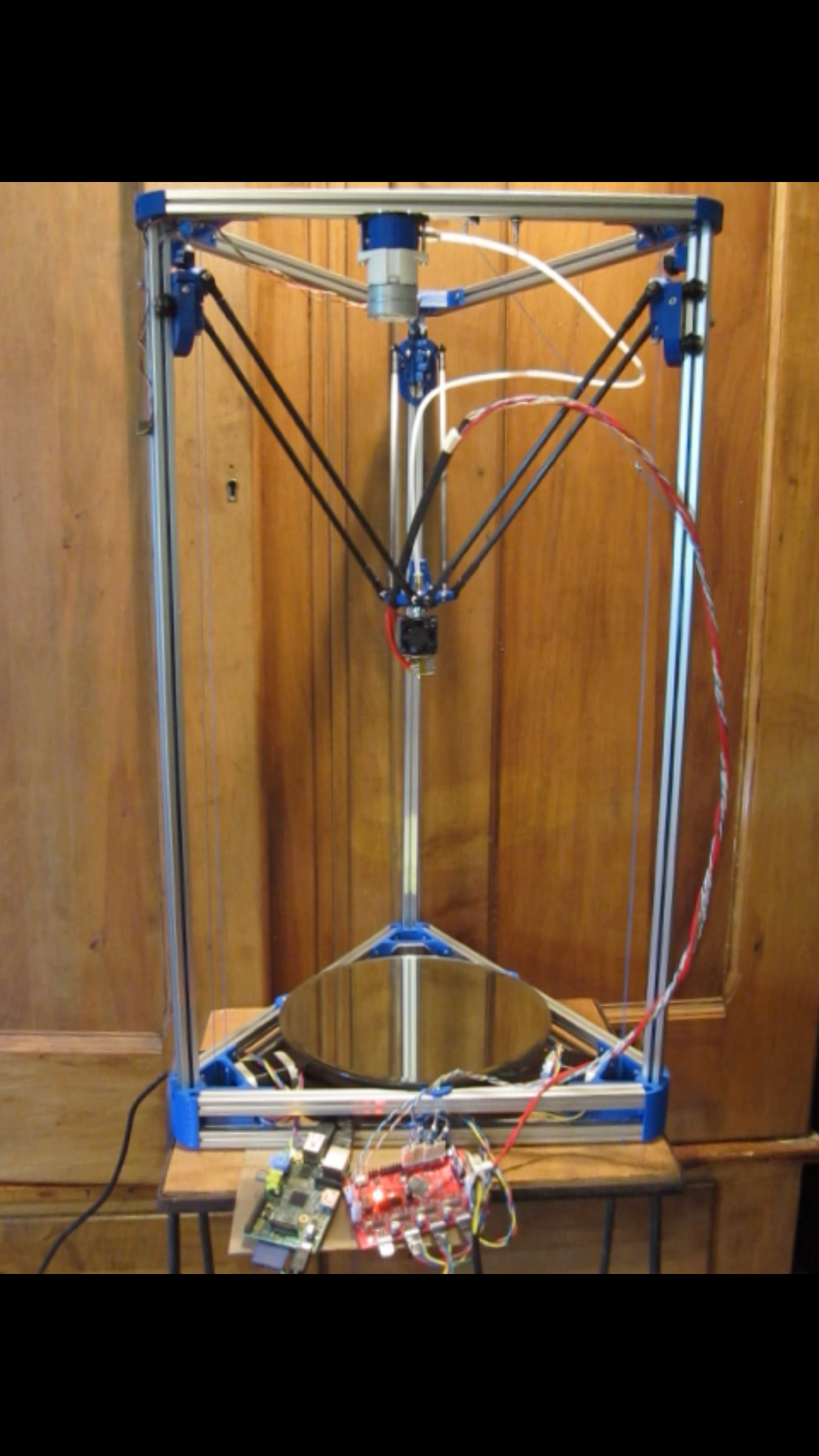

Kossel Deltabot 3D Printer

Early 3D printer

designs have a print-head or "hotend" that is moved by motors in

3 perpendicular directions, along the x, y, and z axes. A more

recent design places the hotend at the end of three arms that

are linked to tracks that allow movement in the vertical plane,

which translates into movement in the x, y, and z axes based on

the coordinated movement of the three arms. This is termed the

"Delta" geometry, and robots of this design are called

Deltabots. There are several advantages to this design and

perhaps a couple of disadvantages.

This Deltabot is a

variant of the Kossel Mini designed by Johann Rocholl, and

includes several customizations intended to reduce cost and

enhance it's versatility. The original Kossel Mini relies on an

aluminum rail and carriage system that is rather costly. The

very first deltabots used ball bearings that rode in the grooves

of the vertical columns, and while the metal on metal contact

was detrimental to the finish on the aluminum, delrin covers

have been developed to allow the bearings to ride in the grooves

without damage. These have been utilized here. The original

Kossel Mini was designed to use timing belts to transfer

movement from the motors to the carriages that ride on the

vertical columns. This build was altered to use 100 lb test

fishing line to reduce cost. This necessitated coming up with a

way to tension excess fishing line, so that the line could be

installed loosely and wound up to tighten it. A screw tensioning

system was devised, similar to a tensioner on a guitar, that

reels in the extra line, and final tension is adjusted as one

would with the stock Kossel, by the small screw at the top of

each column. V-wheel bearings replace timing belt idlers at the

tops of the columns. Many people opt for the J-head hotend on

their deltabots, but the E3D hotend was incorporated here

because of it's all-metal design which provides the potential to

use a wider variety of plastics that have higher melting

temperatures. Because of an ordering mishap during bill of

material changes the PG35l geared stepper motor was purchased

while the extruder components were designed to utilize a new

motor. This required some jerry-rigging to mesh the two

components and yield an operable extruder that would feed the

plastic filament off the reel to the hotend. The Kossel Mini was

equipped with a deployable probe that allowed for auto-leveling

and adapting the print code to the angle of the print surface.

Implementing this probe on this machine was problematic so a new

"direct probe" was designed to allow for direct probing of the

bed surface with the hotend. This probe is based on the design

of a touch probe digitizer used to "scan" 3d parts for CNC work.

An additional adaptation of the Kossel Mini allowed a dremel

flex tool to be mounted in place of the hotend, providing PCB

etching, drilling, and light milling capabilities.